|

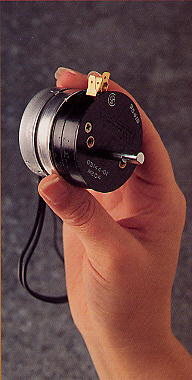

TIMING MOTORS: M Series |

| TIMING MOTORS | |

The Hurst permanent magnet synchronous gear motors used for timer motors are low cost models in popular sizes and mountings, voltages and frequencies that interchange directly with familiar types. With a choice of electrically biased or rugged electromechanical directional systems and with shading bars to offer instantaneous starting (250 milliseconds or less) in the correct direction, this Hurst motor makes an attractive alternative to hysterisis or other motor types.

Dual frequency applications can be met when the 50/60Hz coil is specified. This motor can be used in conjunction with electronic circuitry to control its operation. By rectifying the input voltage to "half-wave," the motor can be stalled indefinitely.

By definition a gear motor is the combination of a motor and gearbox assembly. Building a gear motor begins with assembly of the motor. A precision wound coil assembly is inserted into the stator cup, followed by the rotor assembly, which contains the permanent magnet. The field plate is crimped into place. The completed motor undergoes a series of electrical and mechanical tests. Gearbox assembly begins with the staking of arbor posts into the drawn aluminum case. The gears are then assembled onto the arbors, and the gearbox cover is crimped into place. The proper output pinion or shaft extension is then pressed onto the output shaft. The mating of the motor and gearbox, using our unique locking tab configuration, completes assembly of the gear motor.